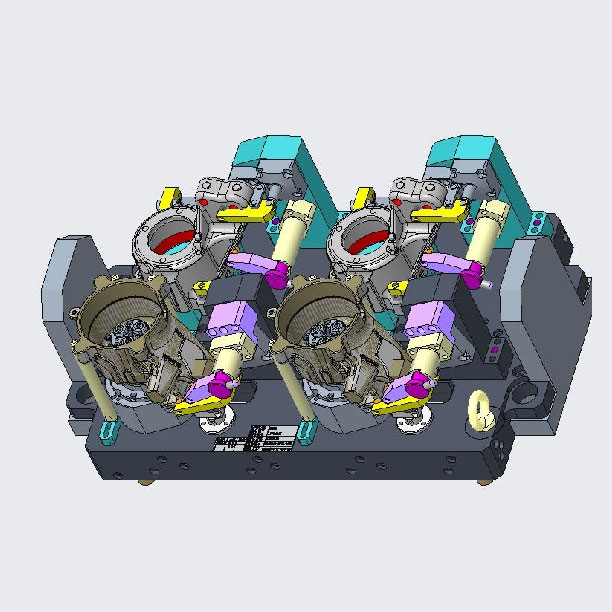

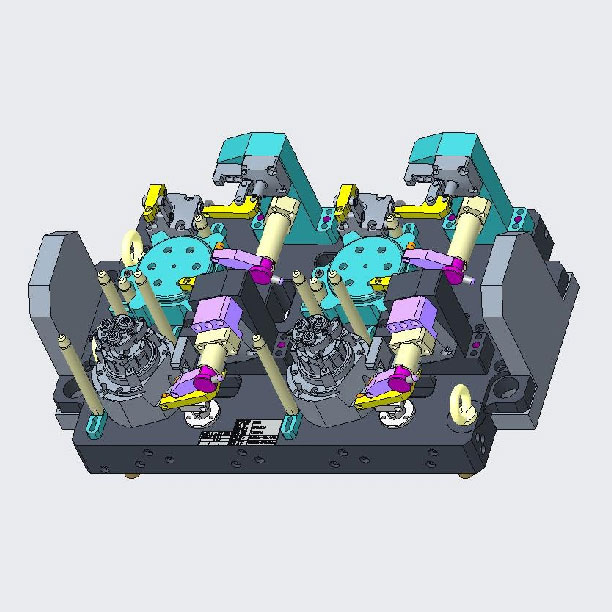

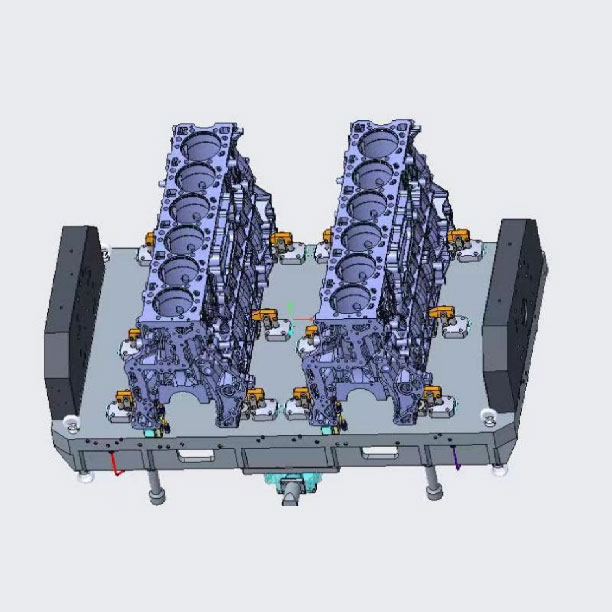

High-Performance Hydraulic Fixtures /jig for Aluminum Castings

High-Performance Hydraulic Fixtures for Die-Casting & Foundry Applications

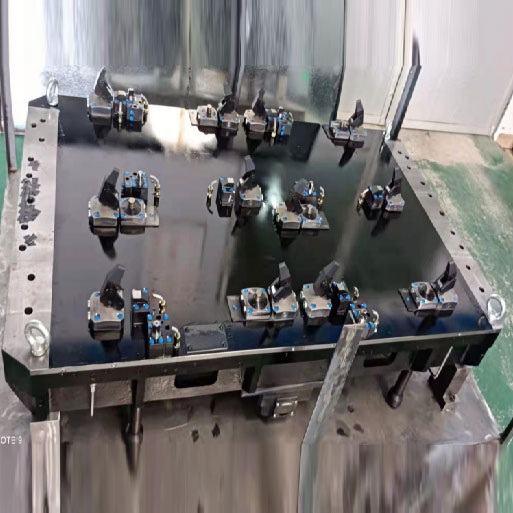

Jinghe specializes in manufacturing precision hydraulic fixtures designed for die-casting, foundries, and aluminum alloy machining. Our fixtures ensure secure clamping, high accuracy, and efficiency for 4-axis and 5-axis CNC machining of cast parts.

Why Choose Our Hydraulic Fixtures?

1. Customized for Die-Casting & Foundry Needs

Perfect for Aluminum Alloy Parts: Ensures stable clamping without deformation

Compatible with 4-Axis & 5-Axis Machines: Ideal for complex machining operations

Optimized for Cast Parts: Accommodates rough surfaces and irregular shapes

2. Precision Engineering & Reliability

High Rigidity Design: Minimizes vibration for superior surface finish

Hydraulic Clamping Force: Consistent and adjustable for different part sizes

Long Service Life: Hardened components resist wear in harsh foundry conditions

3. Fully Customizable Solutions

OEM/ODM Support: Provide your drawings, and we handle the rest

Pre-Shipment Testing: Every fixture is assembled and tested before delivery

Quick Turnaround: Fast production for urgent orders

4. Cost & Efficiency Benefits

Reduces Setup Time: Quick-change design for faster production cycles

Improves Machining Accuracy: Minimizes part movement during high-speed cutting

Low Maintenance: Durable construction reduces downtime

Applications

✔ Aluminum die-cast part machining (automotive, aerospace, electronics)

✔ High-precision CNC milling & turning of cast components

✔ Mass production with repeatable clamping accuracy

Trusted by Foundries & Machining Factories Worldwide – Get Your Quote Today!